GTA Suspension Tolerance Analysis

Graphic Tolerance Analysis is a graphic tolerance analysis software independently developed by Pan-i Information Technology (Shanghai) Co., Ltd. The software is used to help users quickly build dimension chains, GTA automatically judges the increase and decrease rings, and carries out tolerance analysis and calculation. So it predicts the deviation inherent in the design. It also manages and analyses the size data of the analysis. The software will greatly improve the efficiency of tolerance analysis, improve the accuracy of analysis, and play an important role in analyzing historical data.

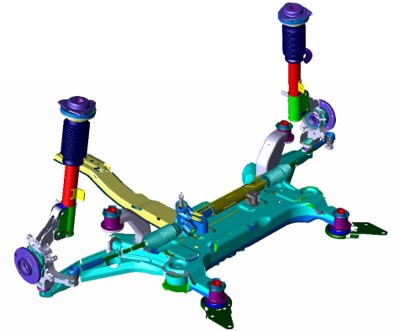

Suspension is the general name of the force transfer connecting device between the frame and the vehicle bridge. Its function is to transfer the supporting force, traction force, braking force and lateral force of the road surface acting on the wheel and the moment caused by these forces to the frame (or body) to ensure the normal driving of the vehicle. There are two methods of suspension tolerance analysis at present:

1、Tolerance analysis based on three-dimensional digital model. The accuracy of calculation results is high. However, the complexity of three-dimensional digital models and the diversity of production and assembly processes often require a lot of time to build 3D models.。

2、Tolerance analysis based on manual calculation. The calculation results are accurate, but convenient, simple and low cost.

For short, flat and fast production cycle, it is urgent to balance the accuracy of tolerance calculation and low cost solutions.

Taking the tolerance study of an automobile suspension as an example, the difficulties in dimension tolerance design are introduced in detail. In this case, the extreme and statistical values of target tolerance are analyzed by fast calculation, which reduces the design cycle and cost of analyzing dimension tolerance of automobile suspension. The design idea of target tolerance of automobile suspension: (1) Determine the structure of automobile suspension; (2) Information input of suspension dimension chain; (3) Automatically judge the logic of dimension chain and Increased and decreased links; (4) Calculate extreme and statistical values of target tolerances, optimize tolerance according to contributor until the design goal is achieved; (5) Automatically generate analysis report.

1.specified input

Dimension chain analysis input:

• Datum;

• Dimensional tolerance;

• Correct link logic 。

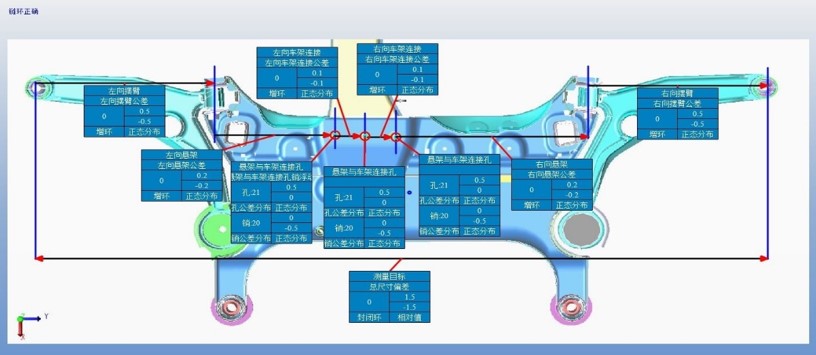

2. Establish dimension chain

Based on the schematic image, a dimension chain is established, including: Datum selection, nominal value, tolerance value and hole-pin floating value, etc. The dimension chain is established, the logic of the dimension chain is judged automatically, and the increase and decrease links of the dimension chain are judged automatically.

3. Tolerance analysis

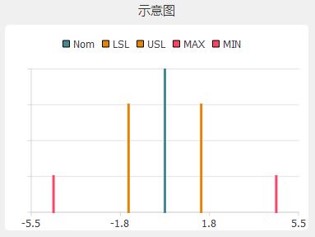

(1) Extreme value method: according to the upper and lower limit deviation of tolerance, the worst closed loop result is obtained.

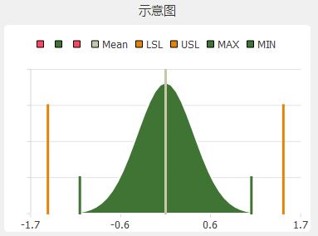

(2) Probability method: tolerance analysis based on RSS analysis method and theory.

(3) Analysis of tolerance contributor:analyze the influence of each component ring on the results.