Oilstone Evaluation

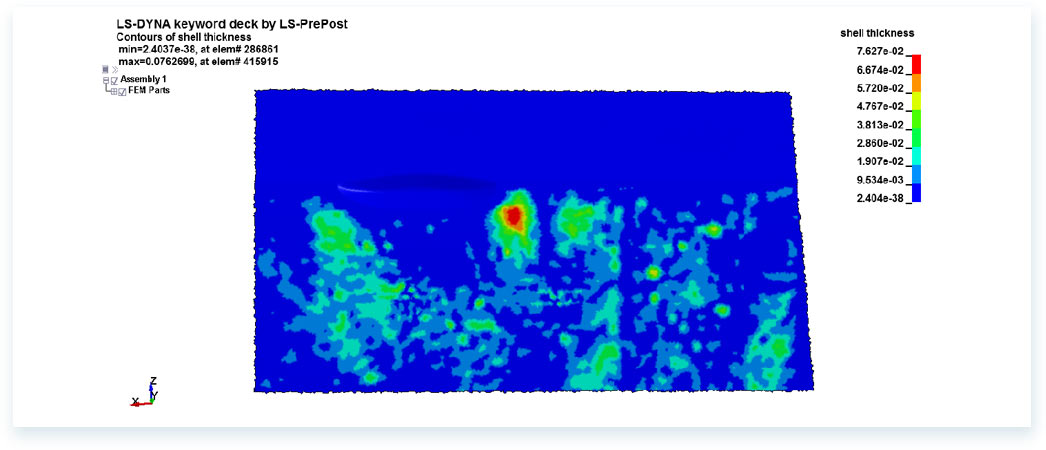

Oilstoneevaluation refers to the evaluation of micro-quality defects of products, oilstone simulation find out the problems and then guides the modification of Die tools.

• Compared with the inner panel, the exterior parts of automobile body not only need to control the dimensional accuracy of the product, but also need to keep the exterior requirements of the product. In the stamping process, engineers often use oilstoneto checkthe smoothness of the products, and the oilstone will leave a clear mark in the position of curvature mutation; such areas will also be directly reflected in the body after spraying paint. However, the current attention in stamping simulation for such problems is much lower than that of response and formability; even if the results are obtained through analysis, it’s just set the pressure compensation zones based on experience. There is not a good method to verify the effect of pressure compensation strategy.

• UsingLs_Dyna to simulate the oilstone results of the stamped sheet, it is necessary to refine the grid of the area before stamping analysis and then turn off grid adaptation during the simulation, and it is necessary to run gravity response before oilstone evaluation. The size and moving direction of oilstone could be defined as you want.

• The appearance quality of the product is very important. The oilstone evaluation of stampede sheet metal in LS-DYNA could predict the problem in advance. The core value points of the solution include:

n The oilstone evaluation simulation can help us discover the microscopic quality defects of stamping parts.

n Ls_Dyan supports local mesh refinement, which can balance speed and accuracy.

n LS-DYNA can support volumetric mesh calculations, which can be used to obtain new pressure compensated surfaces.