Lithium Battery Solution

Lithium battery design is divided into two processes: material design and battery design. Firstly, the material of the battery is designed and optimized from the microscopic scale to obtain the material parameters. Secondly, the performance of the battery is analyzed from the mesoscopic scale. Finally, the material parameters, the performance and electrochemistry, the optimization of the reference electrode position and so on were obtained.

• For increasing the share of renewable energy sources in the future energy mix modern energy storage technologies play a key role. In particular electromobility applications, where mainly lithium-ion batteries are employed, have high demands on capacity, power density, life-time and safety. The time-consuming and expensive experimental development of improved materials and cell designs can be greatly supported by computer simulations of the relevant phenomena. It is thus desirable to estimate the performance of a real battery by studying its virtual counterpart. Moreover, a simulation can help to batter understand the reasons for a particular battery property.

• Most electrodes have similar microstructures and mesoscopic structures, so a complete set of cost-saving and time-saving solutions are urgently needed to understand electrochemistry, electrode performance and battery performance.

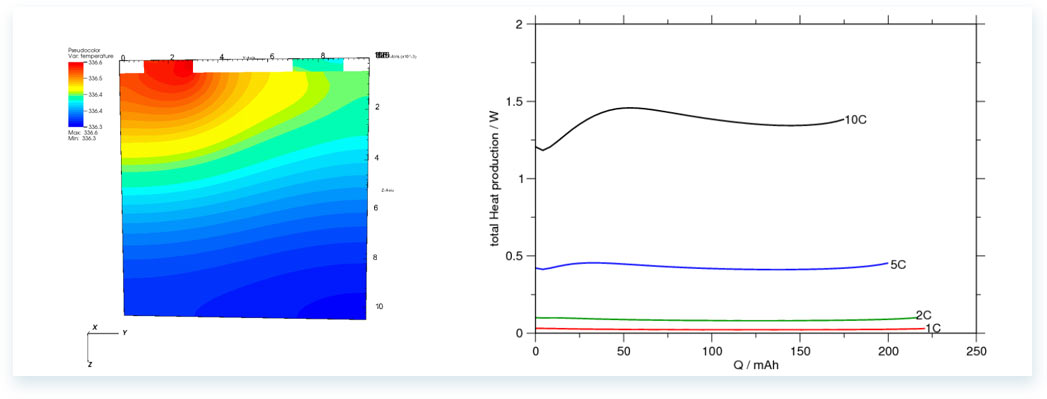

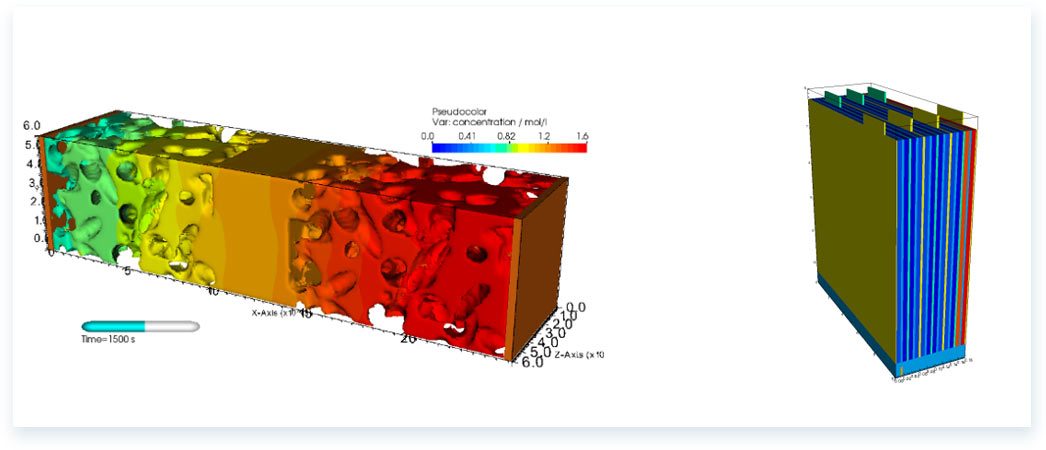

• In the design of lithium batteries, GeoDict and BEST are introduced as the material design and battery design. Design lithium batteries: (1)Determining the material and structure of lithium batteries; (2)Modeling of cathode materials; (3)Simulation analysis of cathode material model by Geodict, including geometric parameters (pore size, pore size, etc.), conductive parameters, saturation parameters, flow parameters (concentration, path, etc.); (4)The performance of the battery was analyzed by BEST, including battery behavior (battery voltage), local electron and potential distribution, ion and current, superpotential, heat source, etc.; (5) Testing and production.

Example for Li-Ion Cathode Battery

1.Determining the material and structure

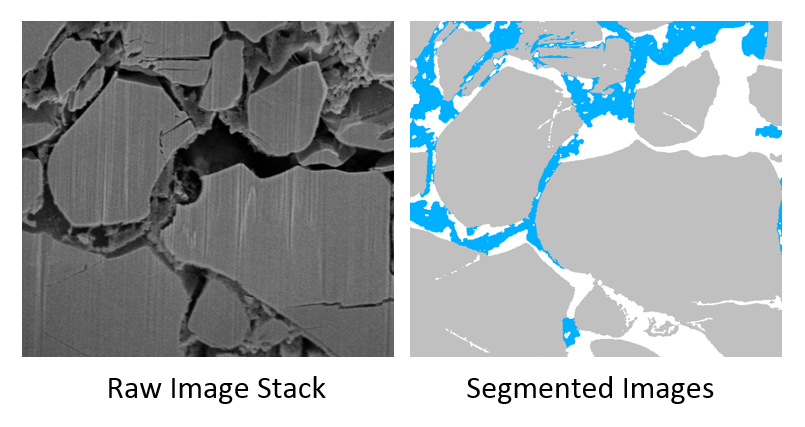

LiCoO2 scanned by SEM. The original 2D image is stacked, segmented and processed to generate three-dimensional material structure. Then, LiCoO2 cathode structure was formed by adding a certain proportion of binder to the three-dimensional material structure.

2. Performance simulation of lithium battery

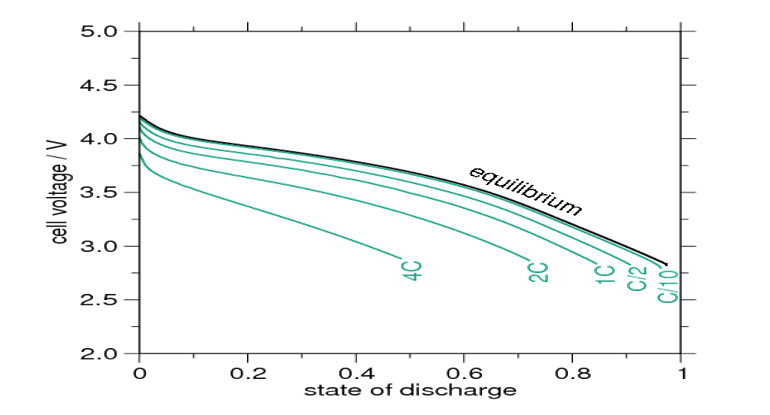

Charging simulation SOC-Voltage

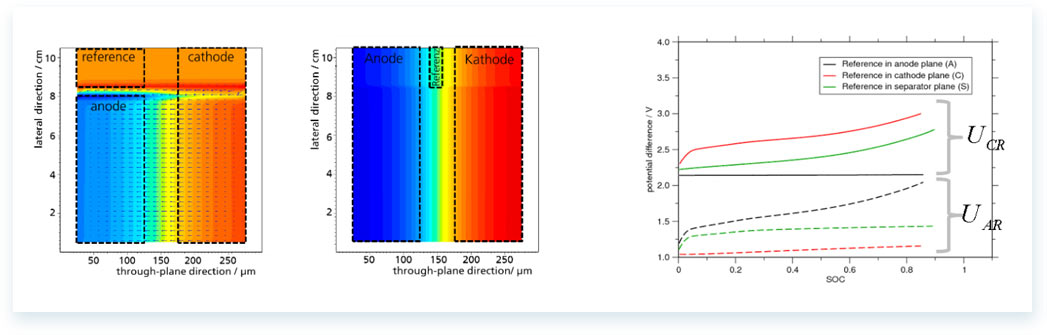

3.Placement of reference electrodes

Considering two locations of reference electrodes, SOC-Voltage curve of two locations are analyzed. It is found that the left image is in the wrong position and the right one is in the right position.

4.Coupling electrochemistry with thermal simulations