3DCS-QDM Closed-Loop System

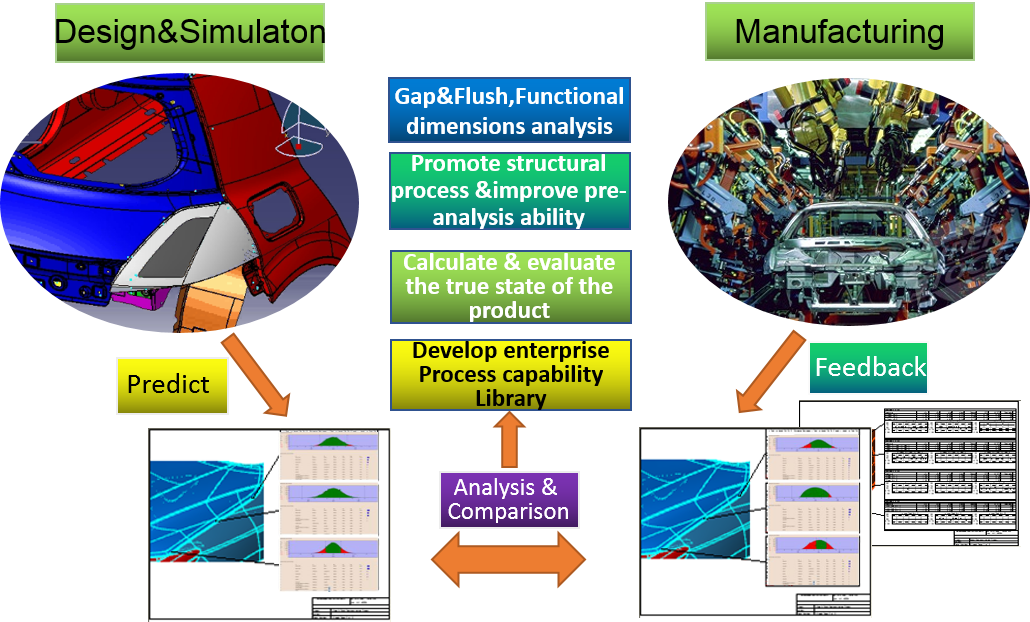

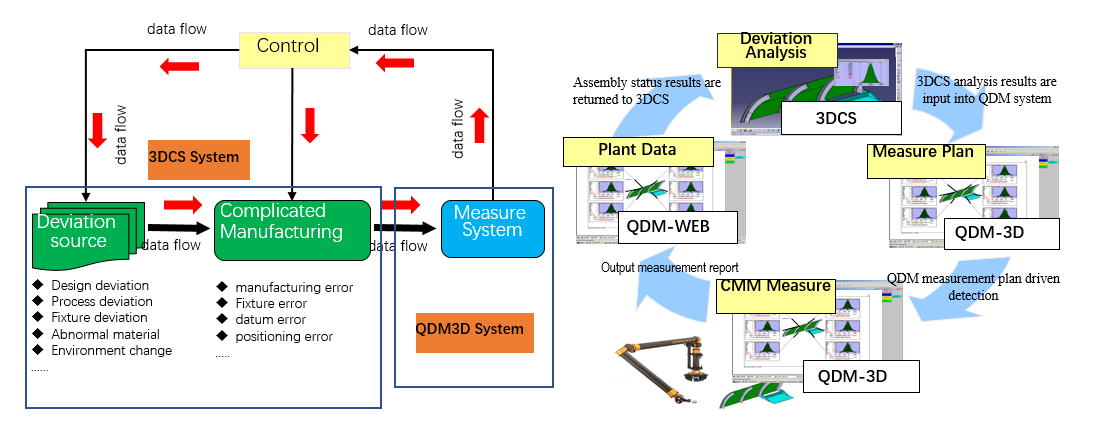

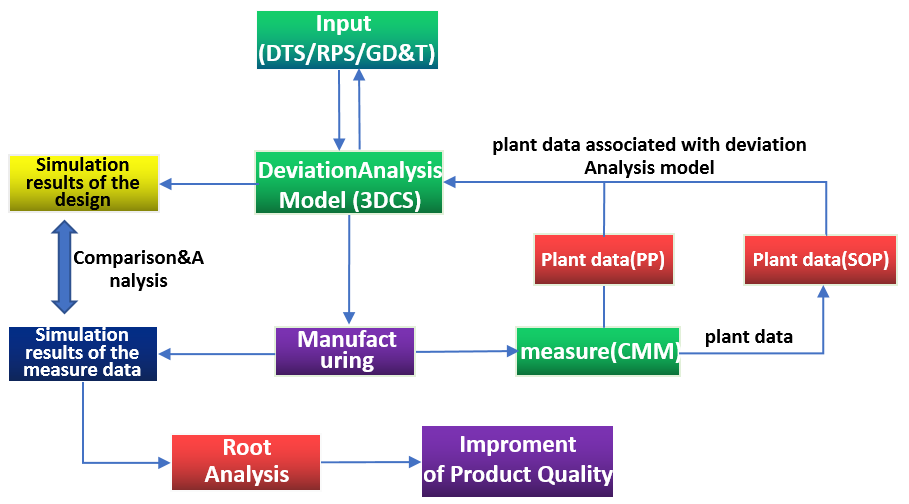

Closed-Loop Variation Analysis System refers to the whole life cycle of the product, with the measurement data as the medium throughout the closed-loop analysis system, feedback up design stage to verify the rationality of the design and improve the structure of the process,and feedback down manufacturing stage to monitor the production process and improve product quality.

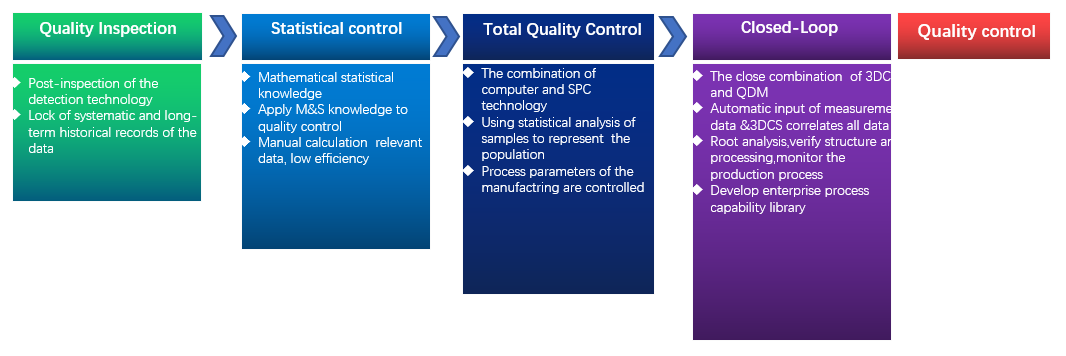

• In the manufacturing process, if the quality is not strictly controlled, it will cause various waste: rework, waiting for materials, repeated production and transportation. Meanwhile,if the quality problem occurs again after the products entering the market, it will cause complaints, rework and repair, claim for compensation, etc. What's more, it will affect the reputation of the enterprise, cause orders reduction and other serious consequences.At present, there are three modes of quality management in the production process of enterprises:

1、Quality Inspection:it mainly relies on the post-inspection of the detection technology. The obvious disadvantages are lack of systematic and long-term historical records of the measurement data in the production process, as well as prevention and economy.

2、Statistical Control:using mathematical statistical knowledge to "prevent", but it mainly uses manual input data and mathematical calculation, thus leading to low efficiency and the error probability of calculation results is large.

3、Total Quality Control(TQC):the close combination of computer and SPC technology can achieve automatic calculation and “prevent” , but the selection of mode sampling method is very important, and only the process parameters of the manufacturing are controlled.The Closed-Loop Analysiss system is the inheritance and development of the above model, which can optimize the structure and processing in the design stage, and monitor the production process of the plant.

• In the enterprise quality management, 3DCS-QDM Closed-Loop Analysis System is created to establish deviation model, carry out comparative analysis and optimization. And it needs to complete the design objectives of the stages in each node of CPMP:

1、Design input satage:according to the relevant technical requirements in the DTS/RPS/GD&T drawings, combined with the actual manufacturing capacity and assembly process , the deviation model is established in the variation analysis software 3DCS.This stage mainly verifies the relevant design inputs.

2、Comparison& Analysis satage:the simulation results based on design input and measurement data are compared to conduct root analysis. In this stage, the critical factors affecting the difference are mainly explored.

3、Optimization stage :according to the contribution of the components to the analysis target, Geofactor, the actual process level and the manufacturing capacity to optimize the manufacturing, assembly process and tolerance development and allocation.

• The establishment of 3DCS-QDM Closed-Loop Analysis System is of great significance to explore the impact of deviation sources and complicated manufacturing systems on product quality and to promote enterprises to create a production mechanism with data-driven quality improvement.It has the following features and advantages:

1、Closed-Loop analysis system involves the whole process of dimensional engineering, with analyzing comprehensively product assembly, appearance quality and functional demands and other critical elements;

uGap&Flush,Functional dimentins analysis.

2、Promote the improvement of structure and process,through the analysis and comparison of measurement and simulation data, improve the pre-analysis ability of enterprises.

uVerify and improve the positioning scheme of components.

uVerify and improve the assembly scheme of parts.

uVerify and optimize the tolerance allocation.

3、Input plant measurement data, calculate and evaluate the real state of the product, perform the later root analysis.

4、Develop enterprise process capability library.