Electronics Assembly

3DCS - Three-Dimensional Deviation Analysis Specialist——Graphical tolerance simulation software.3DCS is the most advanced dimensional deviation analysis tool used to simulate the design, manufacture and assembly of the product, predicting the amount of deviation inherent in the design and determining the source of the deviation.3DCS provides the necessary tolerance analysis methods to predict process changes in an assembly ,identifies the source of additional changes and improves the stableness of the design.ultimately,enabling users to analyze and optimize designs to improve quality and reduce costs early in the design phase.

![201904101554884758134018.jpg 三维偏差分析-·-[-家电行业装配解决方案-]1.jpg](http://enipan.pan-i.com/enpanyi/public/upload/uc/201904101554884758134018.jpg)

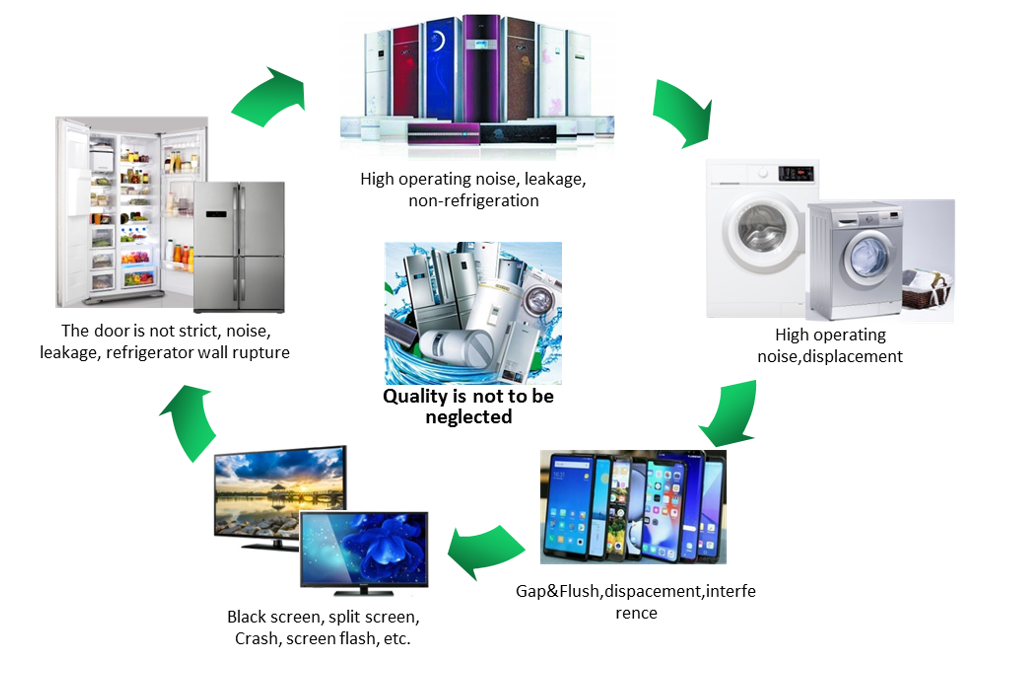

• Electronic products have become a necessary product of modern life, having a huge domestic and foreign market. With the improvement of life quality, users' performance and quality requirements for products are greatly improved, meanwhile, domestic enterprises are faced with the competition from foreign , the enormous survival pressure;According to the authoritative data,the quality of electronics industry is deteriorating year by year,for example,In the refrigerator industry: the door is not strict, noise, leakage, etc.,air conditioning industry: high operating noise, leakage, non-refrigeration.Thus, the sustainable development of enterprises must have their own core technology. The use of dimension engineering, intelligent technology, new materials technology to create first-class quality and product design.Providing good services to occupy the global high-end market for electronics.

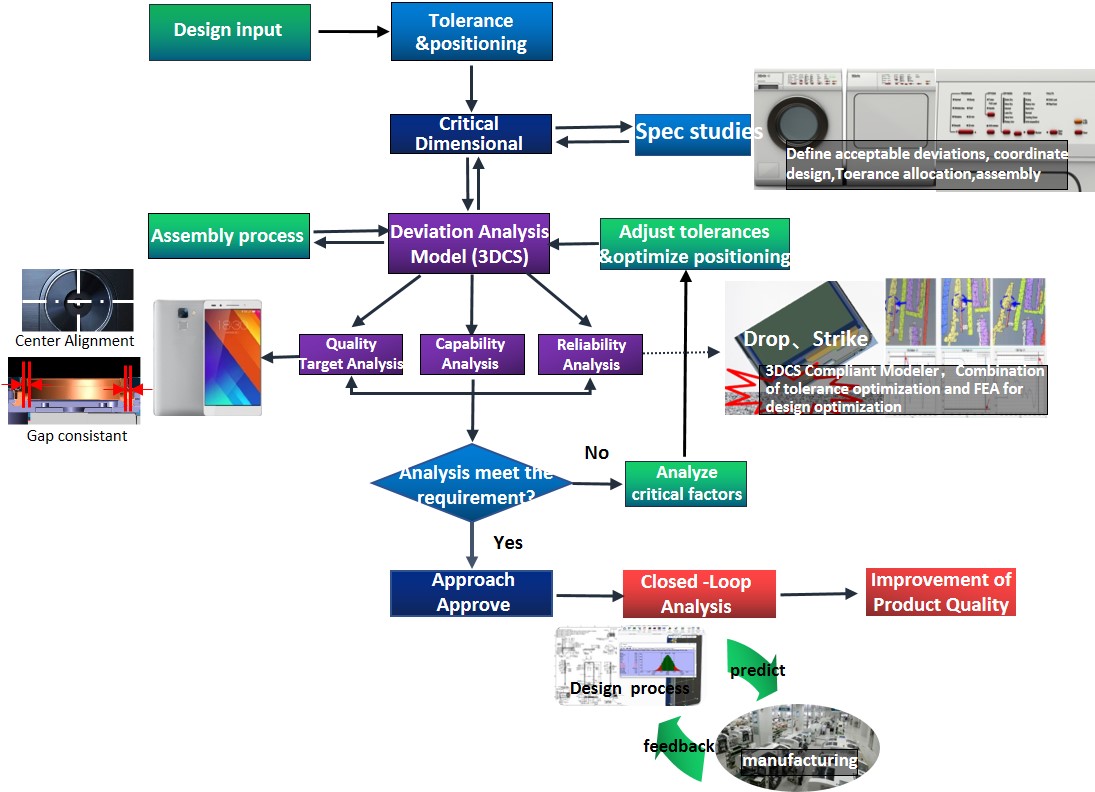

• In the design and assembly of electronic products,tolerance allocation design and optimization ,and improvement of assembly process are an iterative process.Electronic products analysis based on 3DCS requires analysis, verification and optimization of the following contents:

1、design input:the main contents are that the designer according to the technical requirements, relevant standards, assembly process, and Perceived quality to establish a deviation analysis model.then, combined with the analysis results, the accuracy and rationality of the original input are verified.

2、analysis and optimization: the main contents are that the tolerance allocation and assembly process are optimized and improved repeatedly according to the results, and the quality analysis based on the design state is completed.

3、Closed-Loop: associated with plant measurement data,constructing the closed-loop analysis system ,which will further verify and analyze the deviation allocation design and assembly process of the design to promote the continuous improvement of product quality.

• In the design and assembly of electronic , the use of 3DCS Variation Analyst for three-dimensional deviation analysis can ensure the reliability of the design ,meanwhile, greatly improve the design efficiency, compress the project development cycle, and has the following features and advantages:

1、Optimize product design and process

uAllows 3DCS users to pre-evaluate design and assembly concepts and identify possible problems early stage in product development.

uOptimize critical quality characteristics, allowing users to enhance the analysis of critical area tolerances and structural process adjustment.

2、Shorten time cycles and reduce rework costs

uUsing process capability database and product manufacturing capability to create digital virtual prototype.

uThe virtual prototype simulation is used to reduce the physical prototype ,thus reducing the cost, shortening the development time, and accelerating the product delivery to the market.

3、Identify the critical contributors

uDetermine the deviation source and identify the critical contributors.

uMeet the size requirements while maximizing the tolerances of the parts, reducing rework of tools and instruments, minimizing scrap, reducing defects, and thus reducing manufacturing costs.

uBefore the design is released to the entire process of the product, the use of 3DCS to check the function and assembly of components, ensuring the minimum requirements and significantly improve product quality.

4、Continuous improvement in quality

uCreating a closed-loop quality deviation analysis system for associated plant data, fully evaluate the pre-design and post-manufacturing, and establish the enterprise process capability Library.

uCreating a mechanism for data-driven production.