Engine Assembly

3DCS - Three-Dimensional Deviation Analysis Specialist——Graphical tolerance simulation software.3DCS is the most advanced dimensional deviation analysis tool used to simulate the design, manufacture and assembly of the product, predicting the amount of deviation inherent in the design and determining the source of the deviation.3DCS provides the necessary tolerance analysis methods to predict process changes in an assembly ,identifies the source of additional changes and improves the stableness of the design.ultimately,enabling users to analyze and optimize designs to improve quality and reduce costs early in the design phase.

![201904101554883594132516.jpg 三维偏差分析-·[-动力系统装配解决方案-]-1.jpg](http://enipan.pan-i.com/enpanyi/public/upload/uc/201904101554883594132516.jpg)

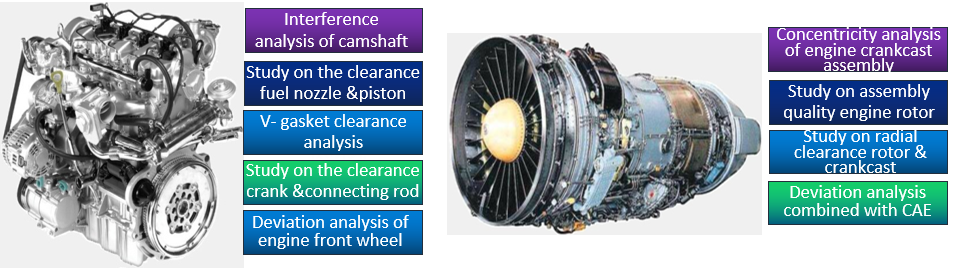

• The manufacturing and assembly of engine system components is a task with high precision. At the same time, it also faces the challenge of maintaining stable operation under complex and adverse conditions.Take aero-engine as an example:aero-engine is a kind of highly complex thermal machinery with large parts dimension, various connectors, complex internal structure, high manufacturing and assembly accuracy, and multiple coordination processes.Meanwhile, in the process of high-speed rotation, the rotor bears huge inertia force, aerodynamic force, thermal load, vibration load and others. These demands undoubtedly make the design, manufacturing and assembly of aero-engine face great challenges.With the advanced 3dimensional deviation analysis tool 3DCS, scientific research has been carried out in the field of automotive engines, aero-engines, wind turbines and other power systems, and a large number of engineering and technical problems have been solved.

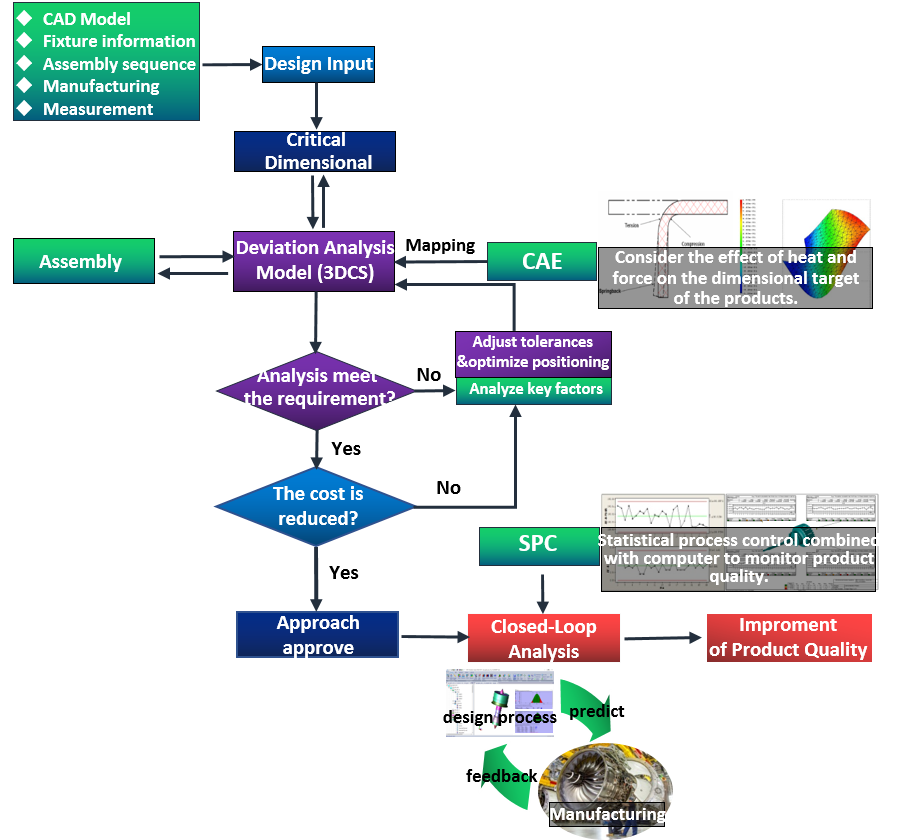

• In the design and assembly of engine,tolerance allocation design and optimization ,and improvement of assembly process are an iterative process. Engine system analysis based on 3DCS requires analysis, verification and optimization of the following contents:

1、design input:the main contents are that the designer according to the technical requirements, relevant standards, assembly process, combined with CAE technology to establish a deviation analysis model.then, combined with the analysis results, the accuracy and rationality of the original input are verified.

2、analysis and optimization:the main contents are that the tolerance allocation and assembly process are optimized and improved repeatedly according to the results, and the quality analysis based on the design state is completed.

3、Closed-Loop:with SPC technology and correlation measurement data,constructing the closed-loop analysis system ,which will further verify and analyze the deviation allocation design and assembly process of the design to promote the continuous improvement of product quality.

• In the design and assembly of engine , the use of 3DCS Variation Analyst for three-dimensional deviation analysis can ensure the reliability of the design ,meanwhile, greatly improve the design efficiency, compress the project development cycle, and has the following features and advantages:

1、Optimize product design and process

uAllows 3DCS users to pre-evaluate design and assembly concepts and identify possible problems early stage in product development.

uOptimize critical quality characteristics, allowing users to enhance the analysis of critical area tolerances and structural process adjustment.

2、Shorten time cycles and reduce rework costs

uUsing process capability database and product manufacturing capability to create digital virtual prototype.

uThe virtual prototype simulation is used to reduce the physical prototype ,thus reducing the cost, shortening the development time, and accelerating the product delivery to the market.

3、Identify the critical contributors

uDetermine the deviation source and identify the critical contributors.

uMeet the size requirements while maximizing the tolerances of the parts, reducing rework of tools and instruments, minimizing scrap, reducing defects, and thus reducing manufacturing costs.

uBefore the design is released to the entire process of the product, the use of 3DCS to check the function and assembly of components, ensuring the minimum requirements and significantly improve product quality.

4、Continuous improvement in quality

uCreating a closed-loop quality deviation analysis system for associated plant data, fully evaluate the pre-design and post-manufacturing, and establish the enterprise process capability Library.

uCreating a mechanism for data-driven production.