Aviation cable virtual laying

Real-time, dynamic simulation and optimization design of brake hoses, efficiently assessing the possible static or dynamic risks of brake hoses, comprehensive monitoring of interference, pulling, over-bending and fatigue damage.

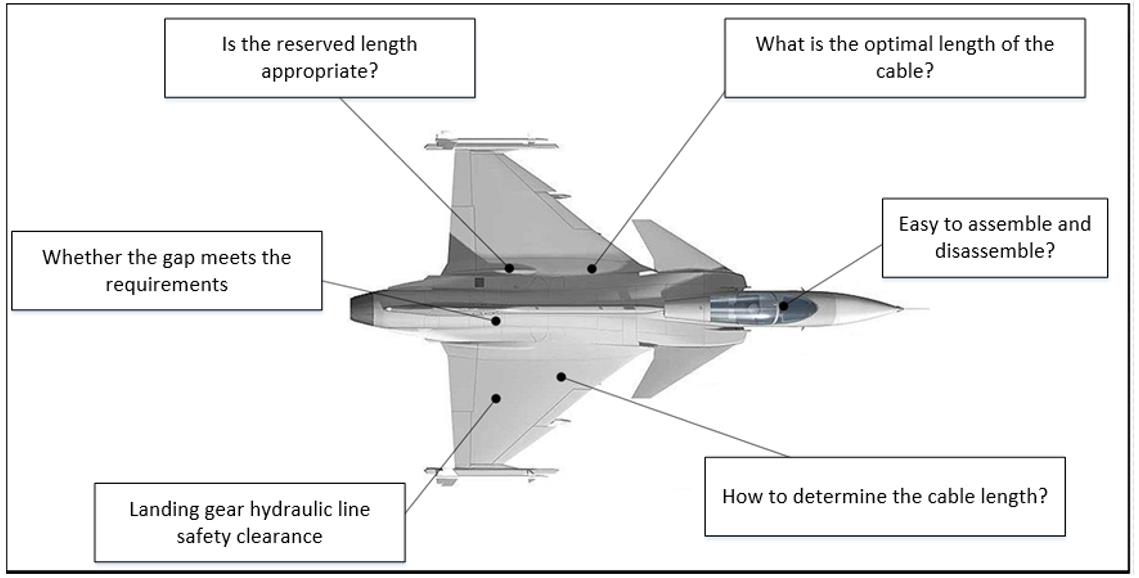

• At present, in the aviation manufacturing industry, virtual assembly technology has been widely used in the assembly simulation of rigid parts. However, for the assembly simulation of flexible cables, there has always been a strong demand, but it has long been trapped in the lack of professional and efficient simulation tools. In recent years, with the increase of the number of products in China's aviation manufacturing industry and the expansion of production scale, the quality and efficiency of aviation cable assembly have been paid more and more attention as an important factor directly affecting production. Taking the fighter machine as an example: the internal space is compact and complicated, resulting in limited cable layout space; the cable is long, the number is large, and multiple compartments are penetrated, and the assembly conditions are complicated; The manufacturing cost of the wire harness is high, the project cycle is compact, and almost no major mistakes in cable rebuilding are allowed; The previous design scheme has not been effectively verified. On-site assembly often has problems such as harness length, branch point position and angle, clamp position and angle, and improper plug connector type.

• In the development of the cable, the advanced flexible cable simulation tool IPS Cable Simulation is introduced. The virtual laying verification of the cable can be divided into the following three parts:

1、Static Verification :This stage is mainly to verify and optimize the length 、the branching angle and position of the harness, the wire harness tension or compression state and the bending radius are verified and optimized also;

2、Dynamic verification : At this stage, dynamic performance checks and optimizations are performed on some sports harnesses, check for risks such as interference, pulling and bending radius being too small, and perform durability analysis;

3、 Assembly verification : This stage is mainly to simulate the wire harness assembly process, verify the feasibility of the assembly process and the reasonable length of the wire harness etc.

• Introducing the IPS Cable Simulation which is a cable virtual layout simulation verification tool into the development of cables, which can find most design problems in the early design stage, reducing cable assembly problems, and improving the quality and efficiency of cable assembly. In addition, there are the following advantages and features:

•The cables created by IPS are flexible after considering the material properties of the cable, the spatial shape is closer to the real shape, making the design change more efficient;

•The simulation is real-time, no need to draw a grid,Real-time optimization design can also be performed while simulating;

•Comprehensive control of various types of risks (pull, interference, fatigue, etc.) that may exist in the static, dynamic and assembly process of the cable;

•The material parameters of the bundled cable can be calculated, and the material parameter database and the clamp database of various constraint types can be conveniently created;

•Statics, dynamics and durability analysis can be performed; cable motion simulation and assembly simulation can be realized;