Complete Vehicle Wiring Harness Virtual Layout

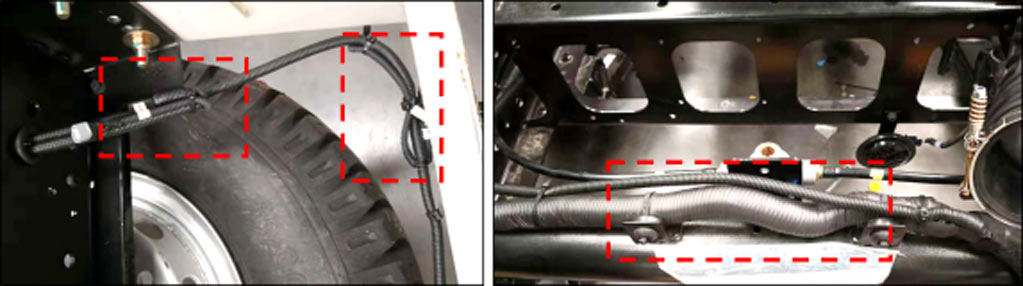

Real-time, dynamic simulation and optimization design of brake hoses, efficiently assessing the possible static or dynamic risks of brake hoses, comprehensive monitoring of interference, pulling, over-bending and fatigue damage.

• The wiring harness layout is usually based on the schematic diagram of the electrical appliance and the distribution of the electrical appliances. The 3D engineer performs the three-dimensional layout of the wiring harness in the CAD software. Since the material properties of the wire harness and the influence of gravity are not considered, problems such as excessive or too short of wire harness length, unreasonable angle or position, and insufficient support points often occur during the trial production process. These often requires engineers to perform repeated rerouting work on site, especially for some moving harnesses or areas where assembly is concerned, and reworks are extraordinarily cumbersome and inefficient.

• During the development of the wire harness, the advanced flexible cable simulation tool IPS Cable Simulation was introduced to simulate the complete vehicle wiring harness virtual layout .

Simulation verification and optimization of three types of wire harnesses:

1、Static Verification :This stage is mainly to verify and optimize the length 、the branching angle and position of the harness, the wire harness tension or compression state and the bending radius;

2、Dynamic verification : At this stage, dynamic performance checks and optimizations are performed on some moving harnesses, checking for risks such as interference, pulling and bending radius, and durability analysis;

3、Assembly verification : This stage is mainly to simulate the wire harness assembly process, verify the feasibility of the assembly process and the reasonable length of the wire harness etc.

• Using IPS Cable Simulation for wire harness virtual layout simulation of the whole vehicle ,it will find most design problems in the early design stage easily, reduce the number of rounds of wire harness trials, greatly reduce the project development cycle, and has the following advantages and features:

•Considering the characteristics of the wire harness material, the wire harness model is flexible, the shape is closer to the real shape, and the design change is efficient;

•The simulation is real-time, no need to draw the grid, no waiting, and optimizing the design in real time while simulating ;

•Comprehensive control of various types of risks (pull, interference, fatigue, etc.) that may exist in the three aspects of static, dynamic and assembly ;

•Support bundling calculation of wire harness material parameters, and facilitate the creation of a database of own material parameters and a dynamic clips database of various constraint types;

•Supporting static, dynamic and durability analysis , realizing motion process simulation and assembly process simulation.