Platform Introduction

“One Model,One Code,Multi-Physics”means LS-DYNA can combine multi-physical and multi-stage analysis in onemodel, it has many calculation methods and MPP(Massively Parallel Processing) analysis. “Multi-physical field” analysismeans coupling analysis of multi-phase & multi-state media and multi-physical fields & multi-scale problems . "multi-stage analysis" and "multi-calculation method" are to solve the problem of accuracy and speed in analysis; "MPP analysis" is to solve the analysis problem of largemodels.

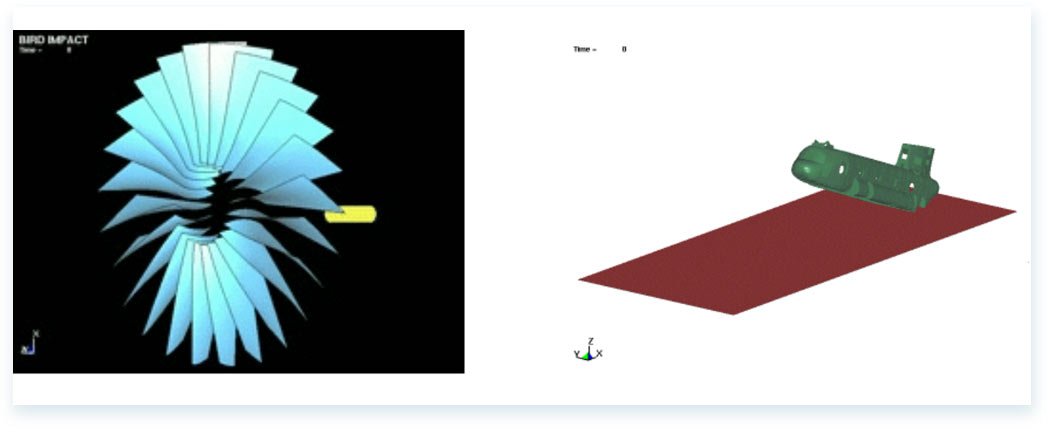

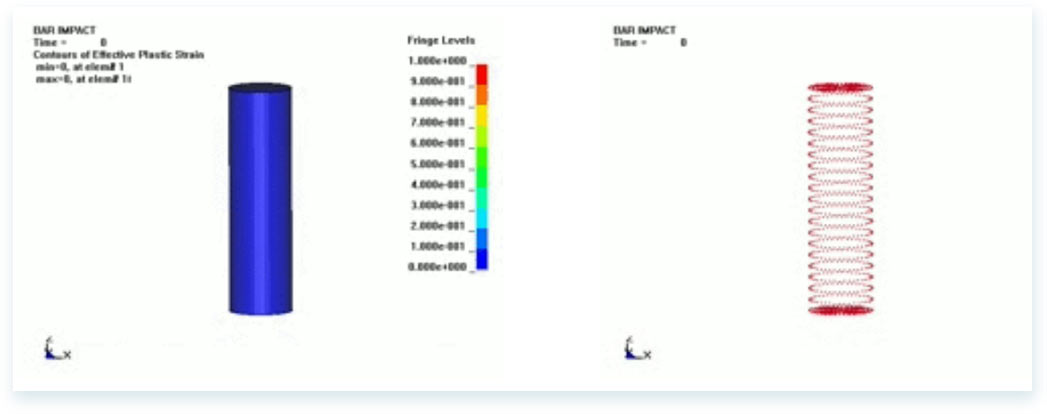

LS-DYNA software is a general finite element program for non-linear dynamic analysis, which is mainly explicit and implicitly supplemented. It is especially suitable for solving non-linear dynamic impact problems of two-dimensional and three-dimensional non-linear structures, such as high-speed collision, explosion and metal forming. And It can also solve heat transfer, fluid-solid coupling problems.

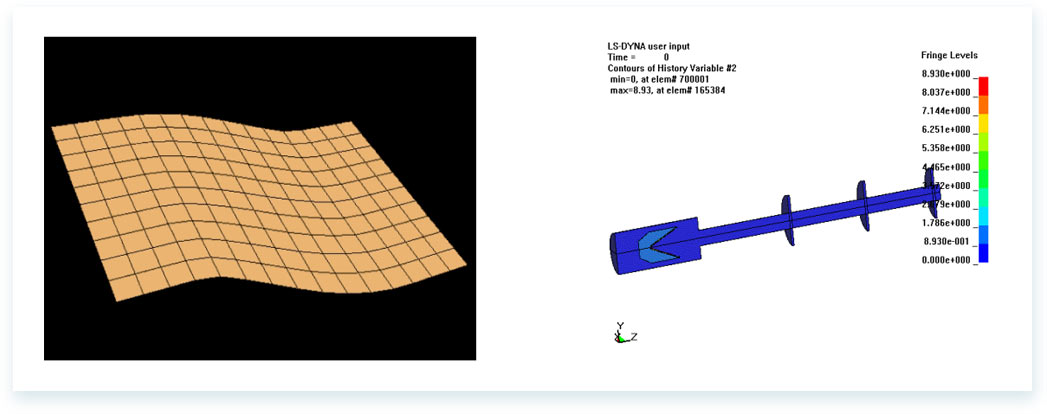

LS-DYNA is a fully functional program which could solve problem of geometric non-linearity (large displacement, large rotation and large strain), material non-linearity (more than 200 material dynamic models) and contact non-linearity (more than 40 contact types). It is mainly based on Lagrange algorithm, but it also has ALE and Euler algorithms. It is major in explicit solution, and it also has the implicit solution function. It is major in structure analysis, and it also has the functions of thermal analysis, fluid and structure coupling analysis. It is mainly based on non-linear dynamic analysis, and it also has static analysis functions (such as pre-stress calculation before dynamic analysis and springback calculation after sheet stamping).

• Analysis Ability

LS-DYNA can simulate the physical properties of many 2-D and 3-D structures:

Nonlinear dynamic analysis, thermal analysis, failure analysis, crack growth analysis, contact analysis, quasi-static analysis, Euler field analysis, arbitrary Lagrange-Euler (ALE) analysis, fluid-structure interaction analysis, incompressible fluid CFD analysis, real-time acoustic field analysis, multi-physical field coupling analysis (structure, heat, fluid, acoustic field, etc.)

• Material Model

The LS-DYNA program now has more than 200 models of metal and non-metallic materials, such as elasticity, elastoplasticity, super elasticity, foam, glass, geology, soil, concrete, fluid, composite materials, explosives and detonation combustion, rigid and user defined materials. Material failure, damage, viscosity, creep, temperature dependence and strain rate dependence can be considered.

• State Equation

Many materials in LS-DYNA material model can be described by equation of state. Normally, the equation of state is not used for structural materials under normal conditions, but it must be used to describe the structural and fluid material which is in high speed(100m/s) or high pressure(6-10Gpa) collision, or in chemical reaction processes(such as materialcombustion).

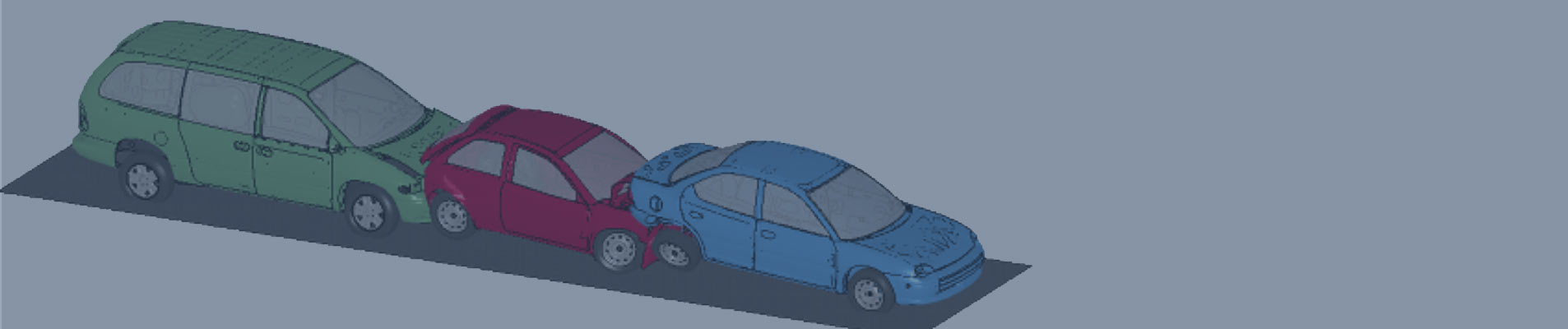

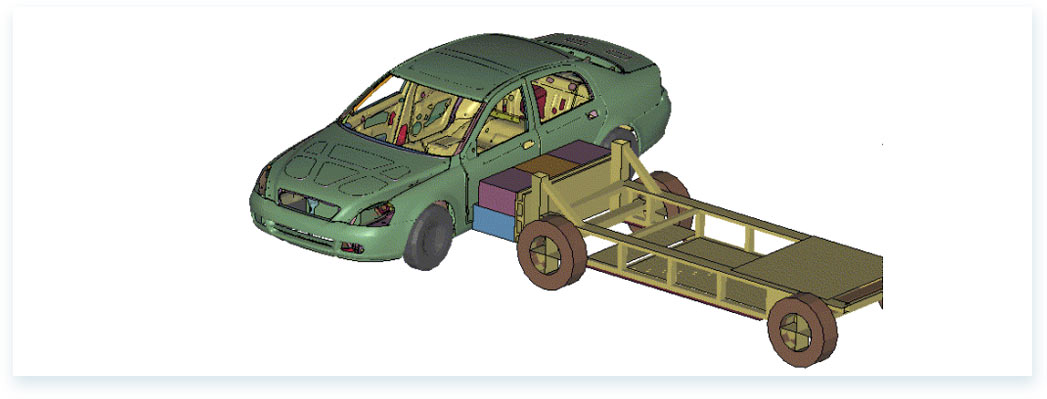

• Application of LS-DYNA in Automobile Industry

Automobile is a large non-linear system which is composed of metal, polymer material, rubber, glass and other components in different ways, such as welding, riveting, articulation, bonding and so on. Analyze the whole vehicle non-linear system is become an indispensable part of modern automobile lean design technology. So LS-DYNA program has become a non-linear analysis system of automobile engineering. It’s main applications are:

• Vehicle Crash Safety Simulation

• Simulation of Vehicle Constraint System

• Nonlinear Dynamics Simulation of Automotive Parts

• Manufacturing Process Simulation and Die Design

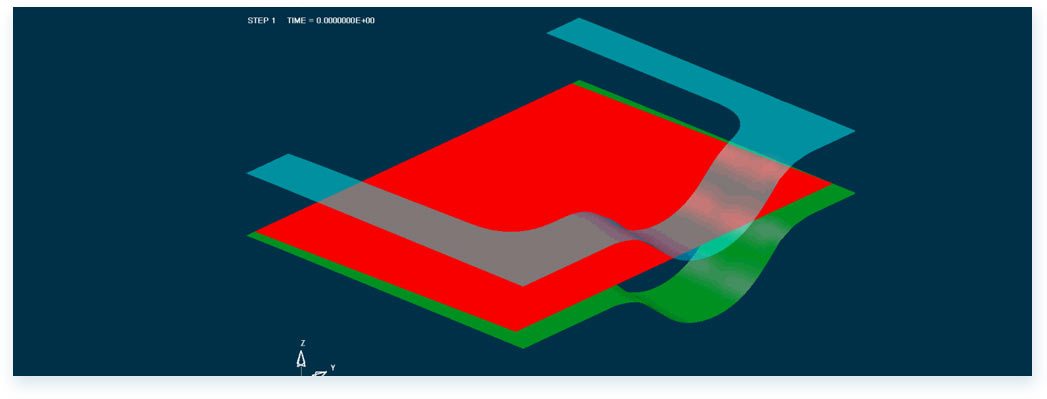

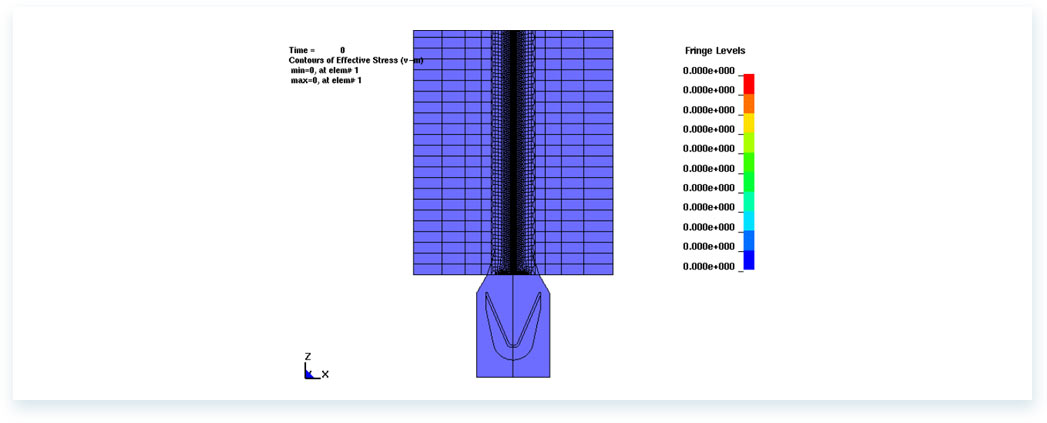

• Application of LS-DYNA in Metal Forming

The application of LS-DYNA in metal forming mainly includes the following aspects:

Sheet forming: including stamping, bending, drawing, pre-bending, trimming, flanging, blow forming, spinning forming, multi-process processing, etc.

Volume forming: including forging, rolling, extrusion, drawing, explosive forming and other volume forming processes;

Special forming: such as hydroforming, etc.

Machining: casting, injection molding, etc.